Freight Doors

Courion offers a multitude of options in freight door design and construction to fit most spaces, loading and class requirements. Courion Freight Doors come in vertical bi-parting and slide-up designs, and steel plate, steel plate insulated and metal clad constructions.

Courion’s standard freight elevator door equipment represents the culmination of over 90 years of experience and progress in the design, manufacture, and installation of power operated freight elevator doors and gates.

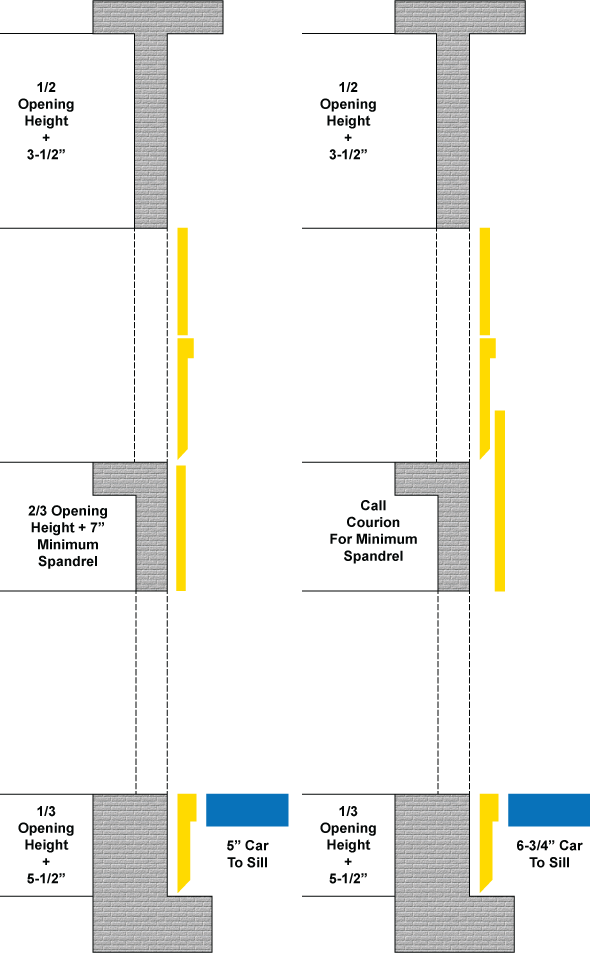

Vertical Bi-Parting Freight Doors

Vertical bi-parting doors provide full opening width access to the inside of the car, but require very little additional hoistway space. Bi-parting doors can be applied in most hoistway situations, including short spandrel heights, shallow pit, and low overheads. The counterbalance of the two door panels ensures smooth operation and long motor life for power doors.

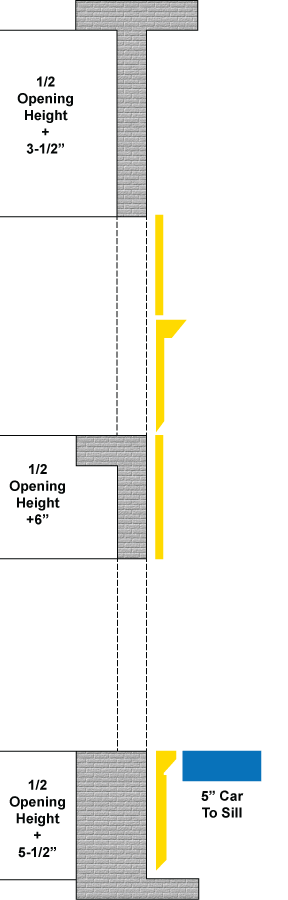

Regular Type Doors

Regular Type Doors have found acceptance world wide. They are used when there is sufficient space available in the hoistway.

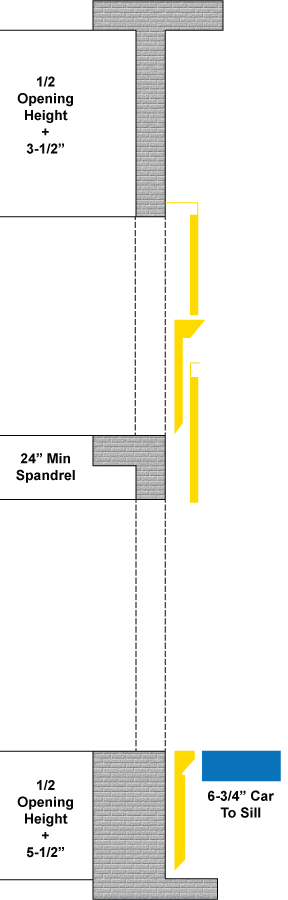

Pass Type Doors

Pass Type Doors are used when the floor-to-floor dimension is restricted. Pass doors allow the use of Bi-Parting doors by having the upper panel at the short floor height offset to pass behind the lower panel of the door above. They are also known as Extended Sill Doors.

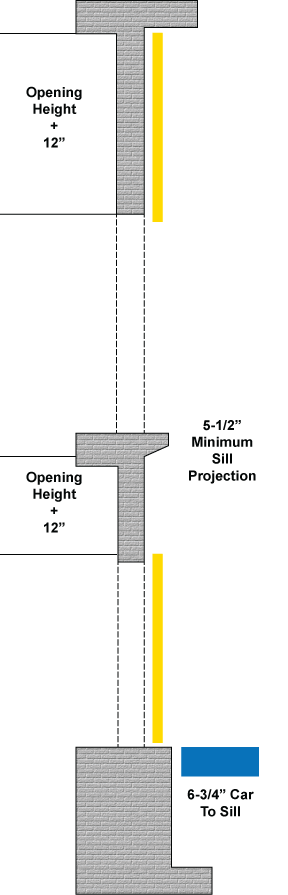

Telescoping Upper Section Doors

Telescoping Upper Section Doors are used at the top landing only, where clear overhead is low. The upper half of the door is in two sections, thus reducing the clear overhead required.

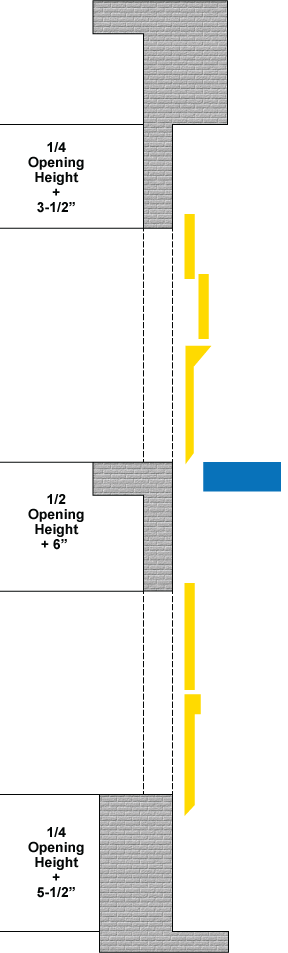

Regular or Pass Type Upper Panel with Compound Lower Panel

(1/3 down, 2/3 up) are used when the pit is less than standard. This door reduces the pit required.

Slide-Up Freight Doors

Single Section Slide-Up Doors

Single Section Slide-Up Doors can be used when the distance between the projecting sill and the underside of the projecting sill above is adequate.

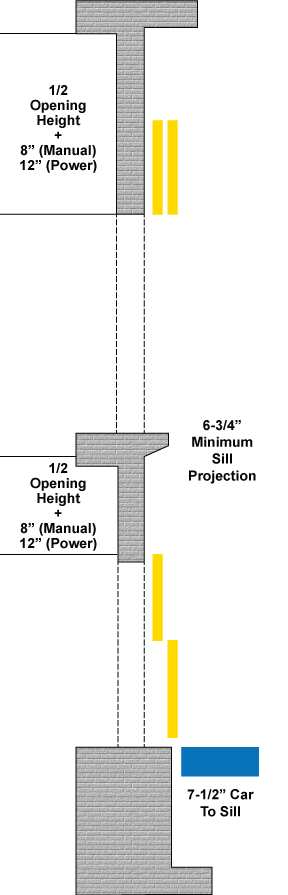

Two Section Slide-Up Doors

Two Section Slide-Up Doors can be used when the clearance available is less than required for Single Section Slide-Up Doors.

Door Construction

There are three basic types of standard door construction available from Courion:

- STEEL PLATE (SP) panels have 12 gauge face sheets welded to reinforced structural steel frames. SP doors are UL and C-UL rated 1-1/2 hour (B).

- STEEL PLATE INSULATED (SPI) panels are similar to SP, with the addition of insulation and a shaft-side steel sheet covering. SPI doors are UL and C-UL rated 1-1/2 hour (B) and heat transmission rated at 650 degrees F maximum temperature rise in 30 minutes.

- METAL CLAD (M-6) panels have wood cores with galvanized steel coverings that provide greater fire resistance and extra resilience. M-6 doors are recommended for general commercial and heavy duty industrial use – except in wet conditions. M-6 doors are quieter and more resistant to serious damage from power trucks. M-6 doors are UL & C-UL rated 1-1/2 hour (B), and heat transmission rated at 250 degrees F maximum temperature rise in 30 minutes.

Door Operator

Courion has combined modern motor technology with design innovation to create the new LP25 Freight Door Operator. It is compact, durable, and easy to install. The motor housing is a totally enclosed, non-ventilated aluminum die cast housing with an integral junction box. The intermittent duty motor has over twice the stall rating of any similar motor in the industry.

Interlock

Courion doors are equipped with an electromechanical interlock, activated by an adjustable retiring cam. Courion’s interlock is NEMA 4, 12, and 13 – standard. Devices with NEMA ratings of 4X, 7, and 9 are available.

Limit Switch

Courion’s new QLS II Limit Switch cuts installation time in half – one switch handles both the Door Open and Door Close function. As with the Courion Interlock, the Courion Limit Switch is NEMA 4, 12, and 13 – standard.

Door Shoes

Courion has finally brought freight door guide shoes out of the stone age. The Courion LF96 Guide Shoes composite design means no more shims or small shoe pieces. The molybdenum surfaces withstand loss of lubrication and eliminates metal on metal clatter.

CARE Automatic Reversing Edge

Courion was the first to introduce a non-contact infrared light curtain for freight elevator doors. The CARE represents a cost effective way to reduce damage to freight elevator doors and car gates.

Auto Sta-Set Switch (Optional)

The Courion Auto Sta-Set Switch prevents lower door panels from being damaged when a heavy weight passes over the freight elevator entry. When activated, the Auto Sta-Set Switch energizes the door motors, causing the door panels to remain in the FULL OPEN position and at rest. The Auto Sta-Set Switch is NEMA 4, 12, and 13 – standard.

Side Opposite Locks

Side Opposite Locks are used to ensure the closed position of the door panels. They are standard on all doors that are 10’ (3000mm) or wider.

Sound Reduction Insulation

To reduce the noise of freight elevator doors, Courion can apply a mastic sound deadening coating to the hoistway side of any door panel.

Door Panel Finishes

Factory 2-part epoxy primer is standard. Also available in stainless steel and a wide range of decorative metal laminates without compromising UL ratings. Typical special finishes include:

- 2-Part Epoxy (color to be specified)

- Powder Coat Enamel (color to be specified)

- #4 Stainless Steel roomside face sheet with factory prime frame

- #4 Stainless Steel roomside face sheet with 2B Stainless Frame

- 2B Stainless Steel roomside face sheet with 2B Stainless Frame

Also available are stainless steel guide rails, chain rods and chain.

Electrical Wiring Packages

Courion can provide you with a customized wiring package that includes pre-marked hoistway and motor wire bundles, and hoistway and cab top junction boxes with marked terminal strips. Optional items include traveling cable, conduit, and fittings. Courion Wiring Packages are tailored to your requirements and needs.

Installation

FREIGHT TECH, LLC., a wholly owned subsidiary of Courion offers “turn-key” installation and repair of any manufacturer’s freight elevator door system. FREIGHT TECH is an I.U.E.C. company with its office in Long Island, New York.

Minimum Space Requirements for Standard Courion Equipment

| Area if Hoistway | Regular Type (Power) | Regular Type (Manual) | Pass Type (Power) | Pass Type (Manual) | 1-Section Slide-Up (Power) | 2-Section Slide-Up (Power) |

| Lintel to Sill Above | 1/2 Frame Opening + 6″ (153mm) | 1/2 Frame Opening + 6″ (153mm) | 24″ (610mm) | 24″ (610mm) | Frame Opening + 12″ (305mm)* | Frame Opening + 16″ (406mm)* |

| Pit Depth | 1/2 Frame Opening + 5-1/2″ (140mm) | 1/2 Frame Opening + 5-1/2″ (140mm) | 1/2 Frame Opening + 5-1/2″ (140mm) | 1/2 Frame Opening + 5-1/2″ (140mm) | n/a | n/a |

| Top Lintel to Overhead | 1/2 Frame Opening + 3-1/2″ (89mm) | 1/2 Frame Opening + 3-1/2″ (89mm) | 1/2 Frame Opening + 3-1/2″ (89mm) | 1/2 Frame Opening + 3-1/2″ (89mm) | Frame Opening + 12″ (305mm) | Frame Opening + 12″ (305mm) |

| Car to Sill | 5″ (127mm) | 5″ (127mm) | 6-3/4″ (172mm) | 6-3/4″ (172mm) | 6-3/4″ (172mm) | 7-1/2″ (190mm) |

| Return | 12″ (305mm) | 11″ (280mm) | 12″ (305mm) | 12″ (305mm) | 12″ (305mm) | 12″ (305mm) |

*On Slide-Up doors. “Lintel to above Sill” is measured from the lintel to the underside of the above projecting sill.

These standards represent minimum space requirements for Courion’s standard freight door equipment. Please contact Courion if your hoistway does not meet these minimum standards and we will be glad to provide you with a customized solution.

Fire Door and Frame Construction Approved By Underwriters Laboratories, Inc.

| Labeled Doors | Certified Doors | |

| Masonry Hoistway | ||

| Steel Plate & Steel Plate Insulated | 13′-6″ (W) x 12′-0″ (H) (4115mm x 3658mm) | 16′-10-1/2″ (W) x 15′-0″ (H) (5145mm x 4572mm) |

| Metal Clad (Wood Core) | 8′-0″ (W) x 10’0″ (H) (2440mm x 3050mm) | 10′-0″ (W) x 12′ -0″ (H) (3050mm x 3658mm) |

| Drywall Hoistway | ||

| Steel Plate & Steel Plate Insulated | 10′-0″ (W) x 10′-6″ (H) (3050mm x 3200mm) | 13′-6 1/2″ (W) x 13′- 1 1/2″ (H) (4130mm x 4000mm) |

| Metal Clad (Wood Core) | 8′-0″ (W) x 10’0″ (H) (2440mm x 3050mm) | 10′-0″ (W) x 12′ -0″ (H) (3050mm x 3658mm) |

Power Arrangement - Bi-Parting Doors

Note: Division 1 locations (explosion resistant) require lap + 11″ (280mm) minimum return with car lap not exceeding 4″ (102mm)

Manual Arrangement - Bi-Parting Doors

Jamb & Wall Requirements

In designing the freight elevator shaft, architects and engineers must keep in mind the special structural requirements of the freight door installation.

Most freight elevator hoistways are of masonry construction. Courion strongly recommends all freight elevator entrances have metal sills and steel jambs that extend to the floor beam above.

Drywall Requirements

Today, however, some designers are using drywall. Courion was the first supplier to offer freight elevator doors that are UL tested and approved for installation in drywall hoistways.

Loading and Class

Bi-parting freight doors are designed to match the capacity and class of loading of the freight elevator as required by Section 2.11.12.4.2 ASME 17A.1-2000. The minimum rated load for bi-parting freight doors is based on the weight and class of the load to be handled, but in no case less than the minimums specified in Section 2.16.2 ASME 17A.1-2000. General explanations of the classes of loading are as follows:

Class A: General Freight Loading.

Where (1) the load is distributed, (2) the weight of any single piece of freight or of any single hand truck and its load is not more than 25% of the rated load of the elevator, and (3) the load is handled on and off the car platform manually or by means of hand trucks.

Class B: Motor Vehicle Loading.

Where the elevator is used solely to carry automobile trucks or passenger automobiles up to the rated capacity of the elevator.

Class C-1: Industrial Truck Loading.

Where (1) the industrial truck travels with the load and (2) the static load (including the industrial truck) during loading and unloading does not exceed the capacity of the elevator.

Class C-2: Industrial Truck Loading.

Where (1) the industrial truck does not travel with the load and (2) the static load (including the industrial truck) during loading and unloading is permitted to exceed the rated load. However, the maximum load during loading and unloading cannot exceed 150% of the rated load.