Cartlift

Courion has provided Healthcare Institutions and Office buildings with the Courion CART-MATIC® Cartlift System. The CART-MATIC® system maximizes delivery payload and can transport a wide range of materials including supplies, meals, mail, surgical instruments and laundry. Expanding or retrofitting the CART-MATIC® system is both feasible and cost effective.

Cartlift Automatic Distribution Systems

Where You Want It, When You Want It!

For over 40 years, Courion has provided Healthcare Institutions and Office Buildings with the Courion CART-MATIC© Cartlift System. The Courion CART-MATIC© Cartlift System offers a programmed floor-to-floor material distribution solution for low, medium, and high-rise applications that need to convey different types of materials efficiently throughout a building. Courion’s CART-MATIC© Cartlift System maximizes your material payload and minimizes the personnel required for material transportation.

Maximize Pay Load Per Cycle

Courion’s CART-MATIC© Cartlift System maximizes your delivered payload. Our lifts are rated at 1000 lbs. capacity with a typical payload in excess of 800 lbs. Typical carts allow for up to 75 square feet of load area.

Courion’s CART-MATIC© Cartlift System can transport a wide range of materials including – supplies, meals, mail, surgical instruments, and laundry. In other words, just about anything your operation requires.

Modernize

Expanding or retrofitting existing systems is both feasible and cost effective. Courion’s CART-MATIC© Cartlift System is compatible with all other brands of material handling systems. If you have an existing cart lift or dumbwaiter system that no longer meets your requirements, Courion has a solution. Courion can modernize or replace your existing AMSCO/Guilbert Cargomaster*, Security, or Peelle Magicart** Lift Systems. Let Courion assist you in revitalizing your vertical material delivery system today.

*AMSCO/Cargomaster is a registered name of American Sterilizer Co.

**Magicart is a registered name of The Peelle Co.

Cartlift Video Tour

CART-MATIC Transfer Unit

Courion’s CART-MATIC© Transfer Unit is designed to load and eject carts consistently and automatically. After the entrance doors and car gate open, the CART-MATIC Transfer Unit’s telescoping assembly extends past the opening and mechanically couples to the underside of the cart. The cart is then automatically pulled into the car and transported to the designated Receiving Floor. Upon arrival, the cart is automatically ejected and the car is ready for its next load.

Talk about saving on manpower! Courion’s CART-MATIC© Transfer Unit eliminates the need for an employee to manually transport a cart from the Service Floor to the Receiving Floor, SAVING THE OWNER BOTH TIME AND MONEY.

Car Enclosure

Courion’s CART-MATIC© car enclosure consists of #16 gauge, #304 stainless steel, #4 finish, with a recessed light fixture. A structural steel reinforced platform is integral with the car enclosure.

All Courion CART-MATIC© car enclosures are fabricated to allow for easy clean-out. There are no unnecessary seams or pockets for dirt to hide. In addition, each car enclosure is factory prepared to receive Courion’s CART-MATIC entrance doors and car gate, cart guidance roller system, cart sensors, and Courion’s CART-MATIC© Transfer Unit.

Entrance Doors and Car Gate

Courion’s CART-MATIC© hoistway entrance units are completely factory assembled and consist of bi- parting roomside stainless steel insulated doors, guides, and entrance frame. Sills on the Courion CART-MATIC© hoistway entrances have recessed cart caster dimples to receive carts. Door jambs are equipped with cart guidance roller assemblies to help guide the cart into the car enclosure.

Courion entrances bear a 1-1/2 hour Underwriters Laboratory “B” label and can be used with either drywall or masonry wall construction.

Cart Guidance System

Courion’s Cart Guidance System starts with the cart caster dimples in the entrance sill plates, moves to the jamb roller guides, and ends with the cart roller assemblies on the side walls of the car enclosure. All are designed to coordinate with one another to insure the consistent and automatic loading and unloading of the material carts.

Door Protection

All Courion CART-MATIC© hoistway entrances are protected by the Courion CARE Automatic Reversing Edge which is attached between the hoistway entrance doors and car gate. The Courion CARE Automatic Reversing Edge is a non-contact light curtain that fills the opening with infra-red light beams. The CARE is an effective solution for reducing damage caused by the movement of the cart.

Courion’s CARE Unit is easy to install and can be added to almost any existing automatic or manual cart system.

CART-MATIC Controller

Courion’s CART-MATIC© Door and Transfer Unit Control is built around an industry proven programmable PLC. Each Courion Controller is customized to your facility’s unique operational procedures. Courion’s controller provides the “smarts” to fully operate the doors, transfer unit, and other operations needed for proper performance of the Courion CART-MATIC© Cart System.

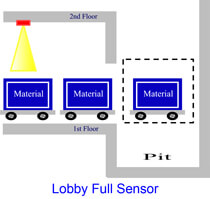

Lobby Full Sensors prevent cart gridlock. Courion’s CART-MATIC© Cart System utilizes information from the Lobby Full Sensors to determine whether there is adequate space at the destination floor for the dispatched cart. If the Lobby Full Sensors indicate sufficient room, the dispatched cart is automatically ejected. On the other hand, if the Lobby Full Sensors indicate that the destination floor is full, a Lobby Full warning is sounded and the cart will not be ejected until the condition is remedied.

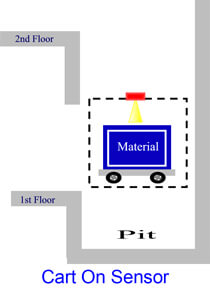

Courion’s Cart ON Sensors ensure that the CART-MATIC© Cart System runs efficiently and with the maximum payload. When a dispatch or return call is registered, the Cart ON Sensors will prevent the lift from leaving the designated floor until the cart is on board and ready for travel.

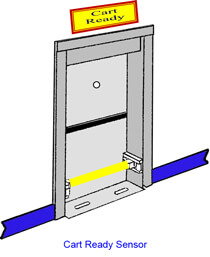

Courion’s Cart READY Sensors perform two important tasks. First, they reduce cart loading problems by indicating to the users that the cart has been properly positioned and is “READY” for dispatch or return. Second, the Cart READY sensors may be set up to act as the automatic call button for the CART-MATIC© Cart System.

Cycle of Operation - Clean Lift (Typical)

<!---->

Automatic Load & Unload (typical)

1. When a cart is in the proper position at the Service Level, a light above the door entrance will illuminate the “Cart READY” light and automatically enter a call for the lift.

2. Upon arrival of the car a flashing light and audible signal will sound and the hoistway doors and car gate will automatically open simultaneously.

3. The Cart-Matic© unit will automatically extend from the car, engage the cart, and pull the cart into the car.

4. When the cart is in the proper position inside the Car as determined by the Cart ON Sensor, a flashing light and audible signal will sound prior to and during the automatic sequential closing of hoistway doors and car gate.

5. Upon arrival of the car at the dispatch level a flashing light and audible signal will sound and the hoistway doors and car gate will automatically open simultaneously.

6. The Cart-Matic© unit will automatically extend from the car and unloads the cart.

7. Lobby Full Sensors are used to detect the presence of more than two (2) additional carts in the Lobby. If the Lobby is full, an audible and light warning will be activated. The hoistway doors and car gate will remain open and the Cart-Matic© unit will not extend until the Lobby Full condition is remedied.

8. After ejecting the cart, a flashing light and audible signal will sound as the Cart-Matic© unit retracts into the car and during the automatic sequential closing of the hoistway doors and car gate.

9. The arrival lantern remains lighted until the car leaves the dispatch floor.

10. The car automatically returns to the Service Level, ready to begin the next dispatch cycle. The next dispatch may be registered as soon as (but not before) the loaded car leaves the Service Level.

Automatic Return (typical)

1. When a cart is in the proper position at a Level other than the Service Level, a light above the door entrance will illuminate the “Cart READY” light and automatically enter a call for the lift.

2. Upon arrival of the car a flashing light and audible signal will sound and the hoistway doors and car gate will automatically open simultaneously.

3. The Cart-Matic© unit will automatically extend from the car, engage the cart, and pull the cart into the car.

4. When the cart is in the proper position inside the Car as determined by the Cart ON Sensor, a flashing light and audible signal will sound prior to and during the automatic sequential closing of hoistway doors and car gate.

5. Upon arrival of the car at the Service Level a flashing light and audible signal will sound and the hoistway doors and car gate will automatically open simultaneously.

6. The Cart-Matic© unit will automatically extend from the car and unload the cart.

7. Lobby Full Sensors are used to detect the presence of more than two (2) additional carts in the Lobby. If the Lobby is full, an audible and light warning will be activated. The hoistway doors and car gate will remain open and the Cart-Matic© unit will not extend until the Lobby Full condition is remedied.

8. After ejecting the cart, a flashing light and audible signal will sound as the Cart-Matic© unit retracts into the car and during the automatic sequential closing of the hoistway doors and car gate.

9. The arrival lantern remains lighted until the car leaves the dispatch floor.

10. The car automatically returns to the Return Level ready to begin the next Return cycle. The next return may be registered as soon as (but not before) the loaded car leaves the Return Level.

Cart Coordination

Cart coordination consists of interfacing an Owner’s new or existing carts with Courion’s CART-MATIC© Cartlift System. A Courion CART COUPLER is REQUIRED on each new or existing cart. The Courion CART COUPLER is attached beneath the cart for coupling with the CART-MATIC transfer device during the load and unload cycle.

- The distance from floor to underside of Cart is to be no less than 6-3/8″ (16mm).

- The distance from floor to underside of the CART COUPLER is to be 4-3/4″ (12mm).

Cart Requirements

- Carts for the CART-MATIC© Cart System must be furnished with straight, continuous, parallel bumpers along each side.

- The cart body or items attached to the cart body must be a minimum of ½” (13mm) inboard from the Cart Bumpers.

- The cart casters must be 5″ or 6″ in diameter. Two (2) of the casters should swivel and two (2) should be rigid.

Although sizes of carts and containers may vary according to material handling requirements, Courion recommends the following minimum/maximum cart sizes for the CART-MATIC© Cart System. Larger or smaller carts can be accommodated. Please contact Courion for additional information.

| Cart Dimensions | Width | Length | Height | Floor to Base | Floor to Coupler |

| MC 49 | 38″ | 51″ | 46″ | 6-3/8″ | 4-3/4″ |

| 71cm | 130cm | 117cm | 16cm | 12cm | |

| MC 75 | 32″ | 68″ | 70″ | 6-3/8″ | 4-3/4″ |

| 81cm | 173cm | 178cm | 16cm | 12cm |

Please note that there are three (3) dimensions that are marked “MAXIMUM” that are to be interpreted as follows: MAXIMUM WIDTH: This shows the maximum bumper width of any cart to be used with the system. After a bumper width is established ALL BUMPER WIDTHS ON THE SYSTEM MUST BE THE SAME. MAXIMUM LENGTH: This shows the maximum length cart which can be placed inside the car. Carts may vary in length from a minimum 38″ (97mm) long to the maximum dimension. MAXIMUM HEIGHT: This shows the maximum height which can be placed inside the car. Carts may vary in height from a simple cart base of 8″ (20mm) to the maximum.

Lobby Space Requirements

IDEAL PLAN FOR MAXIMUM EFFICIENCY ON LOAD AND UNLOAD CART LOBBY STATIONS

The preferred CART-MATIC architectural layout provides ample space on both the Dispatch and Return sides of the Service Level. Generous space on the Return side is particularly desirable since a large number of carts are often returned simultaneously.

The ideal arrangement is an adequate open area restricted to personnel using the CART-MATIC Cart System.

Service Level – Plain View

ASME A17.1a-2005 requires that where a transfer of load is in a nonrestricted area, there shall be a clearance of not less than 48” (1 220mm) between the end of the transferred load and any fixed obstruction in line with the end of the load. ASME A17.1a-2005 7.7.2

Important Notes:

- Allow a minimum 1-1/2 cart lengths for Service Lobby reserved for Dispatch only.

- Allow sufficient space to handle Owner’s scheduled return of carts from all levels to the Service Level

Dispatch/Return Level – Plain View

Important Notes:

- Allow a minimum 2-1/2 cart lengths for Station Level Lobby

Hoistway Door, Car and Shaft Requirements

The following tables contain the minimum dimensional requirements for Courion’s CART-MATIC Cart System. If you are in the planning stages, please use these dimensions for the layout of your CART-MATIC Cart System. If you are modernizing an existing hoistway, please contact one of Courion’s Sales Engineers and we will be glad to help you reach your objectives.

Hydraulic Elevators

| Lift Model # | Capacity | Hoistway Door Frame Dimensions | Inside Car Dimensions | Inside Shaft Dimensions | Pit | Overhead | ||||

| lbs. | Width | Height | Width | Depth | Height | Width | Depth | Depth | Height | |

| CM 49 | 1,000 | 32″ | 48″ | 32″ | 55″ | 48″ | 56″ | 65″ | 60″ | 12′-6″ |

| 81 cm | 122cm | 81cm | 140cm | 122cm | 142cm | 165cm | 152cm | 381cm | ||

| CM 75 | 1,000 | 36″ | 72″ | 36″ | 72″ | 72″ | 60″ | 82″ | 60″ | 12’6″ |

| 91cm | 183cm | 91cm | 183cm | 183cm | 152cm | 208cm | 152cm | 381cm | ||

These dimensions are based on the minimum cart dimensions provided on Page 11 of this brochure. If your cart dimensions are different than those on Page 11, please contact a Courion Sales Engineer for additional information

The above Shaft, Pit, and Overhead dimensions are for a direct or holeless jack hydraulic lift. Depending on the lift manufacturer selected, the shaft, pit, and overhead dimensions may vary slightly from those noted above.

Traction Elevators

| Lift Model # | Capacity | Hoistway Door Frame Dimensions | Inside Car Dimensions | Inside Shaft Dimensions | Pit | Overhead | ||||

| lbs. | Width | Height | Width | Depth | Height | Width | Depth | Depth | Height | |

| CM 49 | 1,000 | 32″ | 48″ | 32″ | 55″ | 48″ | 56″ | 65″ | 60″ | 14′-4″ |

| 81 cm | 122cm | 81cm | 140cm | 122cm | 147cm | 165cm | 152cm | 437cm | ||

| CM 75 | 1,000 | 36″ | 72″ | 36″ | 72″ | 72″ | 60″ | 82″ | 60″ | 12’6″ |

| 91cm | 183cm | 91cm | 183cm | 183cm | 157cm | 208cm | 152cm | 528cm | ||

These dimensions are based on the minimum cart dimensions provided on Page 11 of this brochure. If your cart dimensions are different than those on Page 11, please contact a Courion Sales Engineer for additional information

The above Shaft, Pit, and Overhead dimensions are for a traction lift. Depending on the lift manufacturer selected, the shaft, pit, and overhead dimensions may vary slightly from those noted above.

Vertical Transportation Speed

The selection of vertical transportation equipment is a function of many variables, including the physical space available for the CART-MATIC Cart System, the nature of material to be moved by the CART-MATIC Cart System, the number of landings to be served, and the total travel required between floor levels.

The tables below provide the suggested Feet Per Minute and the total cycle time for a round trip of the CART-MATIC lift assuming a 12’-0” floor height. The efficient movement of materials must be tailored to the needs and design of the individual owner. Courion’s sales engineers are available to consult with architects and owners to help them set and reach their objectives.

Machine Room Requirements

Machine Room dimensions vary based on the size and type of building. Courion suggests that a machine room for a CART-MATIC Cart System provide the minimum space: One Car = 11’-0” x 12’-0” Two Cars = 15’-0” x 14’-0”.

- 4’0″ x 6’8″ Door self closing and locking

- Light switch & conventional outlit

- Disconnect & Fusing

- 120 VAC Light supply – dedicated circuit

- Courion Door & CART-MATIC Controller

- Elevator Controller

- Hydraulic or Traction Power Unit

Minimum Space Requirements - Plan & Elevation

- HOISTWAY DOOR WIDTH: Width of a Cart plus 4″ (10cm)

- CAR WIDTH:Width of a Cart plus 4″ (10cm)

- CAR DEPTH: Length of a Cart plus 4″ (10cm)

- SHAFT WIDTH: Width of a Cart plus 24″ (61cm) for Hydraulic Lifts and 26″ (66cm) for Traction Lifts

- SHAFT DEPTH: Length of Car plus 10″ (26cm)

- INTERLOCK & CAM AREA: 8″ x 16″ (minimum)

- CLEAR OVERHEAD: 1-1/12 times the door height plus 3′-6″ (107cm) plus space required for lift equipment

- DOOR & GATE OPERATOR AREA: 1/2 the door height plus 16″ (41cm)

- CAR HEIGHT: Height of CART plus 2″(5cm)

- HOISTWAY DOOR HEIGHT: Height if Cart plus 2″ (5cm)

- PIT DEPTH: 1/2 the Door Height plus 4″ (10cm) plus additional space required for lift equipment